Digital frame measuring tools transform automotive repair, especially collision and car body work, by offering unprecedented precision for accurate repairs, material sourcing optimization, reduced waste, lower costs, and faster turnaround times. This technology is invaluable in streamlining workflows, enhancing customer satisfaction, and revolutionizing both modern and classic car restoration processes, particularly in tire services.

In today’s digital era, embracing innovative tools like digital frame measuring is transforming modern repairs. This technology offers unprecedented precision and accuracy in repair estimates, ensuring cost-effective solutions without compromising quality. Furthermore, it streamlines material sourcing and inventory management, enabling efficient workflows and faster turnaround times. By integrating digital frame measuring into their processes, repair professionals can enhance efficiency, reduce errors, and better serve their clients.

- Precision and Accuracy in Repair Estimates

- Efficient Material Sourcing and Inventory Management

- Streamlined Workflow for Faster Turnaround Times

Precision and Accuracy in Repair Estimates

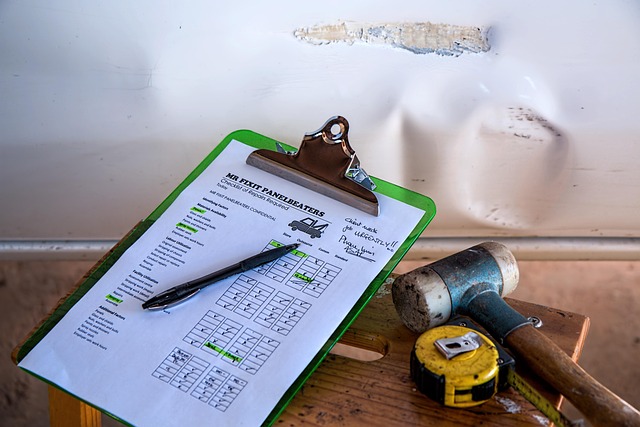

In the realm of modern repairs, particularly in automotive body work and car collision repair, digital frame measuring tools have become indispensable. These innovative devices offer a precision and accuracy that traditional measuring methods simply cannot match. By employing digital frame measuring, auto body shops can provide more exact repair estimates, ensuring clients receive fair and comprehensive pricing based on meticulous assessments.

This advanced technology allows for detailed measurements of vehicle frames, enabling technicians to identify even the slightest distortions or deformities caused by collisions. With such precision, auto body shops can tailor their repairs to specific needs, enhancing overall quality and customer satisfaction. In a competitive market where every detail matters, digital frame measuring stands out as a game-changer in the auto body shop landscape.

Efficient Material Sourcing and Inventory Management

In the realm of modern repairs, especially for vehicle bodywork like car damage repair and collision damage repair, efficient material sourcing and inventory management are paramount to success. Digital frame measuring tools have emerged as game-changers in this regard. By utilizing advanced digital technologies, these tools enable precise measurements of damaged components, facilitating accurate material requirements. This not only reduces the chances of errors but also optimizes inventory levels by ensuring that only the necessary parts are ordered, minimizing waste and cost overheads.

The integration of digital frame measuring into collision damage repair processes enhances overall efficiency. It allows for quick identification of needed materials, expediting the procurement process. Moreover, real-time data on inventory ensures that shops are never left short of critical components, leading to smoother workflows and improved customer satisfaction in vehicle bodywork repairs.

Streamlined Workflow for Faster Turnaround Times

In modern repairs, adopting digital frame measuring technologies offers a streamlined workflow that significantly enhances turnaround times. Traditional methods often involve manual measurements and adjustments, leading to delays and potential errors. Digital tools, however, automate this process, providing precise dimensions and ensuring consistent results. With just a few clicks, technicians can capture accurate data for parts replacement or modification in both automotive repair and classic car restoration.

This efficiency is particularly valuable in tire services where quick turnaround times are critical. Digital frame measuring enables mechanics to swiftly assess tire wear, identify issues, and prescribe solutions. As a result, customers benefit from faster service without compromising on quality, ensuring their vehicles are back on the road promptly.

Digital frame measuring is transforming modern repairs by offering unparalleled precision, efficiency, and speed. By leveraging this technology, repair professionals can provide accurate estimates, optimize material sourcing and inventory management, and streamline workflows, ultimately leading to faster turnaround times and enhanced customer satisfaction. Embracing digital frame measuring is a crucial step towards revolutionizing the repair industry.